3D Printing vs. Plastic Injection Molding: Differences and Comparison

Neither plastic injection molding nor 3D printing is a one-size-fits-all approach to production. In determining which method to adopt, the pros and cons of both should be weighed to do an effective comparison. 3D printing is an additive manufacturing process. Each step involves the addition of new layers of thermoplastic, resin, or other materials until the print is completed. Plastic injection molding requires a mold to be created first. Then a thermoplastic is heated to melting temperature before it is injected into a mold through a pressurized nozzle.

3D printing technology is a cheaper alternative to injection molding. However, when it comes to speed, plastic injection molding is more profitable, provided that the mold is already prepared. But if the mold is not ready, 3D printing may become the preferred choice. Therefore the speed in both processes is conditional. 3D printing is best for rapid prototyping while plastic injection molding will do exceedingly well when it comes to high-volume production of parts. This article will further discuss the differences between 3D printing vs. plastic injection molding, their advantages, disadvantages, and alternatives.

3D Printing Definition and Comparison to Plastic Injection Molding

3D printing creates objects by the successive addition of layers of thermoplastic materials on the build surface of the printer. The concept of 3D printing technology dates back to the early 1980s. Hideo Kodama, in Japan, discovered a layer-by-layer method of manufacturing. He used a photosensitive resin and cured it under UV light. Today, 3D printing works with CAD software which creates the digital model of the object. Then, a slicing software interprets this data in the actual build process, until it is complete. When a proof of concept is required, it is more convenient to use 3D printing instead of plastic injection molding. The reason is that it has a shorter lead time. For more information, see our guide on what is 3D printing.

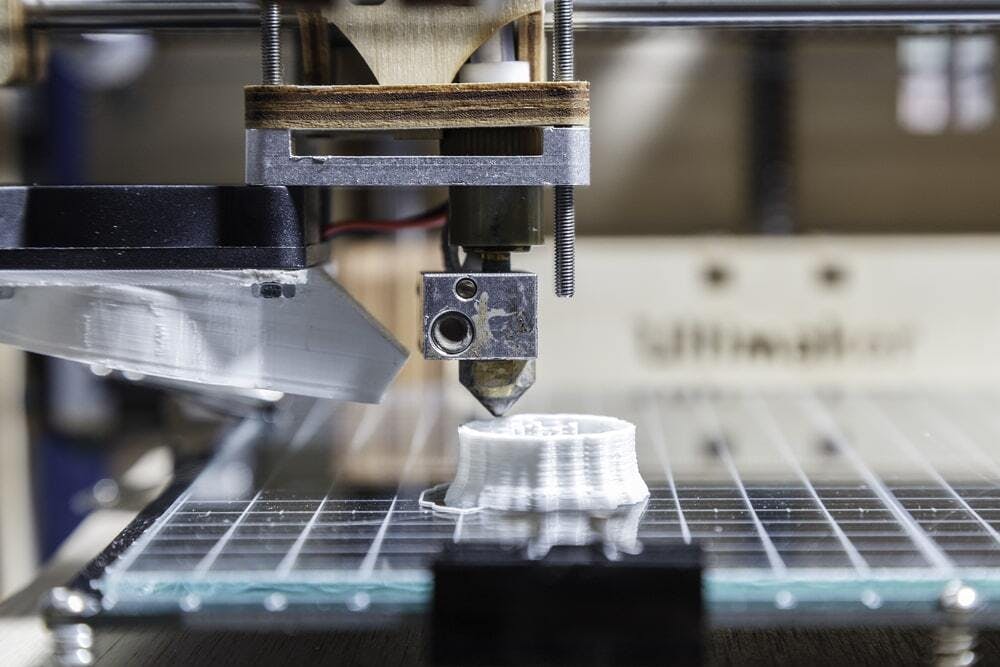

Figure 1 is an example of a 3D printer:

A 3D printer.

Image Credit: Shutterstock.com/Sergi Lopez Roig

What Are the Advantages of 3D Printing Compared to Plastic Injection Molding?

These are some of the advantages of 3D printing over plastic injection molding:

- 3D printing produces parts with a higher degree of tolerance than those of plastic injection molding.

- 3D printing can produce parts faster compared to plastic injection molding.

What Are the Disadvantages of 3D Printing Compared to Plastic Injection Molding?

Some of the disadvantages of 3D printing over plastic injection molding:

- Plastic injection molding is suited for high-volume production compared to 3D printing.

- The 3D printers have smaller build areas compared to plastic injection molding machines. This limits 3D printers in producing large objects.

Plastic Injection Molding Definition and Comparison to 3D Printing

Plastic injection molding works by filling a mold with melted thermoplastic material. This molten material cools and hardens before being ejected. The first injection molding machine was created and patented by Isaiah and John Hyatt in 1872. It was used in the production of small objects like combs and buttons. This paved the way for the development of plastic manufacturing companies. Plastic injection molding is the preferred choice over 3D printing when it comes to the mass production of parts. For more information, see our guide on what is plastic injection molding.

Figure 2 is an example of a plastic injection molding machine:

Plastic injection molding machine.

Image Credit: Shutterstock.com/mofaez

What Are the Advantages of Plastic Injection Molding Compared to 3D Printing?

Some of the advantages of plastic injection molding compared to 3D printing are:

- Plastic injection molding allows for repeatability, and produced parts have a smoother surface finish than 3D printing.

- Plastic injection molding can produce larger volumes of parts than 3D printing.

What Are the Disadvantages of Plastic Injection Molding Compared to 3D Printing?

The disadvantage of plastic injection molding compared to 3D printing are:

- Plastic injection molding has a higher entry cost than 3D printing.

- It is expensive and time-consuming to make design changes, especially when there is a mistake to be rectified with plastic injection molding.

Comparison Table Between 3D Printing and Plastic Injection Molding

Table 1 below shows some basic attributes when comparing 3D printing vs. plastic injection molding:

High entry cost

No

Yes

Well suited to design changes

Yes

No

Good for complex and intricate designs

Yes

No

Suitable when a large number of parts are needed

No

Yes

Smoother surface finish

No

Yes

More intricate and complex designs can be achieved with 3D printing compared to plastic injection molding. The mold in plastic injection molding also comes at a high price.

3D Printing vs. Plastic Injection Molding: Lead Cost Comparison

3D printing is less expensive than plastic injection molding. The tooling cost of injection molding can be expensive. This is a result of the aluminum or steel mold that must be machined to create the inverse of the required part or object.

3D Printing vs. Plastic Injection Molding: Speed Comparison

An injection molding machine will not be useful until the mold is ready for production. This causes a delay that 3D printing technology can capitalize on in terms of speed. But once the mold has been designed, injection molding becomes the best choice. The setup allows more parts to be produced in a shorter period of time.

3D Printing vs. Plastic Injection Molding: Volume Comparison

3D printing is a slower process, so fewer parts can be produced compared to plastic injection molding (with a functional mold). Plastic injection molding makes large-scale production of parts possible.

3D Printing vs. Plastic Injection Molding: Materials Comparison

When it comes to the materials for the design and build process, both offer a wide range of materials. It should be noted that the specific material needed depends on what is being made.

What are the Mutual Alternatives to 3D Printing and Plastic Injection Molding?

One mutual alternative to 3D printing and plastic injection molding is:

- Vacuum Forming: Vacuum forming technology uses a vacuum to stretch a heated sheet (heated to its glass transition temperature) over the surface of a mold. At this temperature, it becomes soft (not melted) and malleable. Vacuum forming is similar to 3D printing, in that they are both used for the rapid prototyping of designs. Also, vacuum forming and plastic injection molding produce parts with good tolerance.

What Are the Similarities Between 3D Printing and Plastic Injection Molding?

Some similarities between 3D printing and plastic injection molding are:

- In both 3D printing and injection molding, the thermoplastics are heated to the melting temperature.

- A large range of materials is readily available for both processes.

What Are the Other Comparisons for 3D Printing Besides Plastic Injection Molding?

Another comparison for 3D printing is:

- 3D Printing vs. CNC Machining: This is a subtractive manufacturing process that involves the removal of materials from a solid workpiece until the final object is formed. Like 3D printing, CNC machining can also produce functional parts. For more information, see our guide on 3D Printing vs. CNC Machining.

What Are the Other Comparisons for Plastic Injection Molding Besides 3D Printing?

Another comparison for plastic injection molding is:

- Plastic Injection Molding vs. Compression Molding: Compression molding uses a two-part mold, where molds are heated to help cure the product while also heating the charge before compression. Like plastic injection molding, compression molding also produces plastic parts using heat and pressure. For more information, see our guide on Plastic Injection Molding vs. Compression Molding.

Summary

This article presented the differences between 3D printing and plastic injection molding, explained what they are, and discussed each process has different attributes. To learn more about 3D printing and plastic injection molding, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.